3D printers can create harmful fumes

FFF 3D printers are a major source of VOCs and ultrafine particles, both of which can be harmful to your health. While this can vary drastically on the filament type, it is still advised to reduce your exposure to 3D printer fumes. There’s a continued research effort in comparing 3D printing filament emissions with each other.

The number of studies regarding 3D printer emissions is still relatively small, and has until very recently only considered basic filament types such as PLA and ABS1. PLA is fairly benign, as it mostly consists of mostly harmless components. Acrylonitrile butadiene styrene (ABS), as the name suggests, emits large amounts of styrene when heated. Hardly any studies have compared these filament types with the more modern alternatives on the market. I was especially interested in the performance of PETG, and I’ve found this study that has a closer look.

Particle size distribution (PSD), particle number concentration (PNC), particle chemical composition and particle volatility were measured. In addition, volatile and very volatile organic compounds (VOCs and VVOCs) emitted during 3D printing were analysed.2

The results were rather interesting. Here are the types of filaments they tested:

- ABS – Acrylonitrile butadiene styrene

- ULTRAT – Acrylonitrile butadiene styrene + 0–3% polycarbonate

- ASA – Acrylonitrile styrene acrylate

- HIPS – High-impact polystyrene

- PETG – Polyethylene terephthalate glycol

- GLASS – 80% PETG + 8–12% fibre glass filings

- PCABS – 30–35% polycarbonate + 55–65% ABS

- ESD – PETG + carbon-based conductive additives

Notable are two things. One being that styrene is a common component of 3D printer filament, the second is an absence of PLA. The latter can probably be explained because earlier studies have already established its emission profile to an adequate degree. It is, however, still somewhat disappointing, as it makes direct comparisons more difficult.

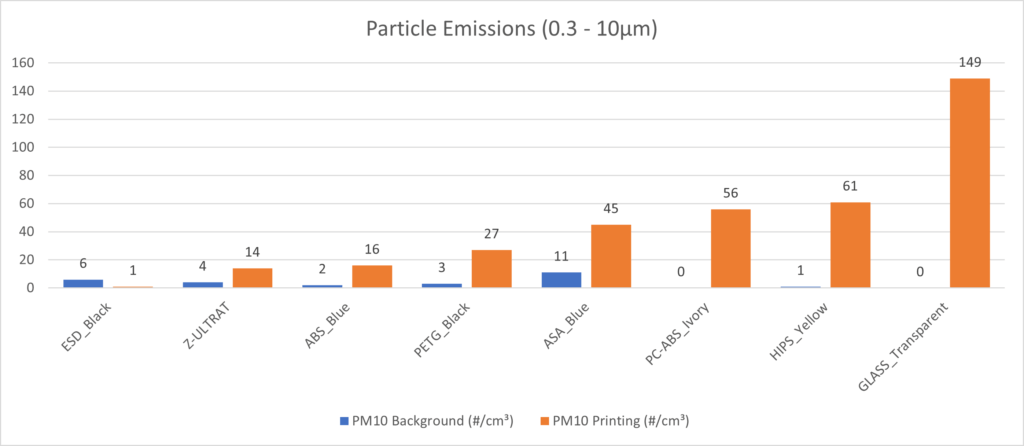

Particle Emissions

Fine Particle Emissions (0.3–10 µm)

First up, we have the amount of particle emissions created by the different filaments. The measurements were taken with two different devices, and thus two different sized scales. The number of particulates created between 0,3 – 10 µm was relatively low:

Because of their small size, particles on the order of 10 micrometers or fewer (coarse particulate matter, PM10) can penetrate the deepest part of the lungs, such as the bronchioles or alveoli. When asthmatics are exposed to these conditions, it can trigger bronchoconstriction.3

Especially, long-term exposure to these particulates should be avoided, which is why it is commonly recommended to run 3D printers only in well-ventilated areas. That is the easiest method of reducing the total number of particulates in the air, and also the cheapest. There are several alternatives, such as running the 3D printer in an enclosure or filtering either the air inside the enclosure or the room the 3D printer is located in through an air filtration system.

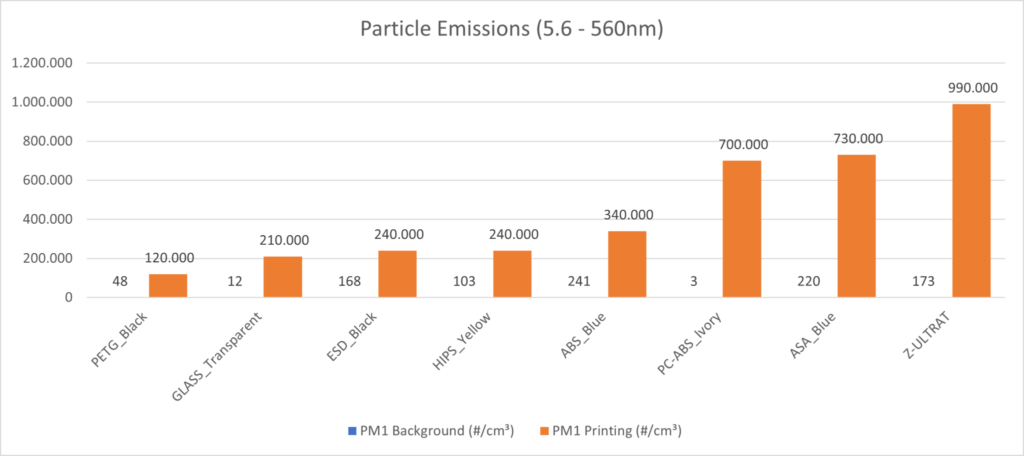

Ultra Fine Particle Emissions (5.6–560 nm)

The second category of particle emissions is that of the ultra-fine particles. These range between 5.6 to 560 nm.

The inhalation of ultra-fine particles should also be avoided, especially when suffering from various forms of lung disease.

The main exposure to UFPs is through inhalation. Owing to their size, UFPs are considered to be respirable particles. Contrary to the behaviour of inhaled PM10 and PM2.5, ultrafine particles are deposited in the lungs, where they have the ability to penetrate tissue and undergo interstitialization, or to be absorbed directly into the bloodstream — and therefore are not easily removed from the body and may have immediate effect. Exposure to UFPs, even if components are not very toxic, may cause oxidative stress, inflammatory mediator release, and could induce heart disease, lung disease, and other systemic effects.2

These types of particulates are more difficult to filter from air due to their size, but HEPA filters can still reduce their numbers, especially when recycling the contaminated air through the filter medium repeatedly.4

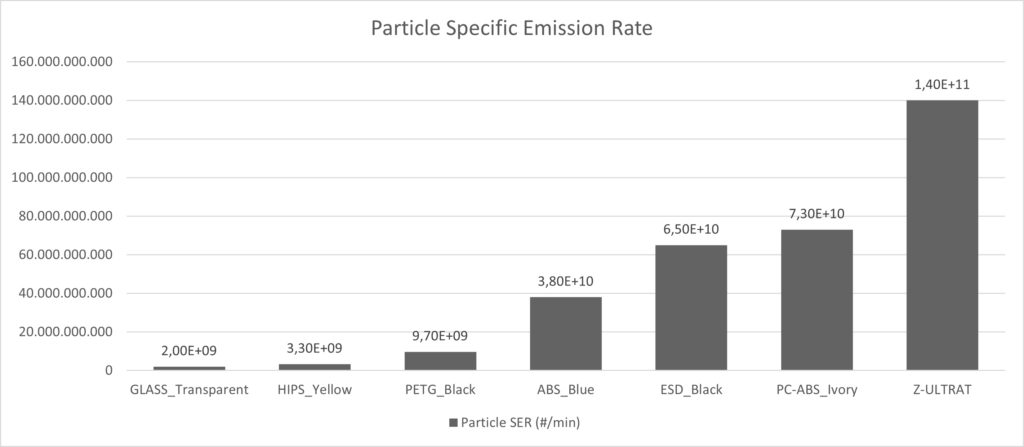

Particle-Specific Emission Rate

The SER is based on the emission of particles in the size range of 5.6-560 nm.

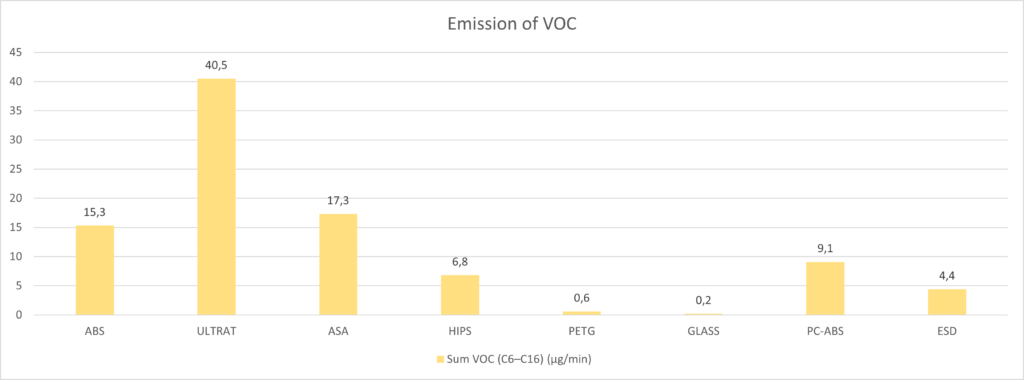

VOC Emissions

VOCs, or Volatile Organic Compounds, aren’t inherently dangerous or problematic by themselves. Most smells and odours are actually of VOCs. This does not mean they cannot be dangerous, however. Respiratory, allergic, or immune effects in infants or children are associated with man-made VOCs and other indoor or outdoor air pollutants. Some VOCs, such as styrene and limonene, can react with nitrogen oxides or with ozone to produce new oxidation products and secondary aerosols, which can cause sensory irritation symptoms.5

3D printing with PETG and GLASS was related with low TVOC emission, while high emission rates were found for ULTRAT, ASA and ABS. The most abundant VOC was styrene for most of the filaments except PETG-based filaments (PETG, GLASS and ESD). In addition, for the eight filaments, benzaldehyde (8 times), acetophenone (6 times), ethylbenzene (5 times), toluene (5 times), and other C3-benzenes (5 times) were detected.2

Styrene, being a major component of ABS and ASA-based filaments, inevitably leads to an increased emission of this VOC during printing.

Interestingly, even filaments based on the same type of material (plain ABS and ULTRAT) showed different amounts of emissions, albeit under different printing conditions:

Filaments that have the same basic polymers may show different VOC emission profiles: For instance, ABS and ULTRAT are mainly based on ABS polymer, and while the main monomers styrene and acrylonitrile were often detected, both the TVOC emission rates and other major VOCs differed. The printing temperatures of ABS and ULTRAT are also different (275 °C vs. 260 °C). Therefore, no conclusion can be drawn whether the subtle difference in the filament composition, the printing temperatures, or other undefined factors are contributing to the different VOC emissions. The same is found for PETG and ESD, which are both PETG-based materials.2

This might suggest that many other “special blends” of filaments can introduce more VOC emissions. This is likely because of additives such as stabilizers, lubricants, mineral oils, antioxidants, and colourants. Most notably again is the performance of PETG, with only trace amounts of VOCs.

VOC can be filtered using activated carbon filters.6 These filters are usually one of the filter stages found in most air filtration systems and are very efficient. Do note that they lose their efficiency over time, as they become saturated. That is why it is necessary to replace them regularly.

Conclusion

While 3D printing is unlikely to be directly harmful to your health, precautions should still be considered, especially when considering long-term exposure. That is especially true when printing with the nastier types of filament, primarily those with styrene as a major component. Luckily, PETG seems to be a viable alternative to many ABS-based filaments these days. Not only do its characteristics match or exceed that of ABS, but its emission profile is also much less hazardous.

Regardless of what filament you choose, you should always take common safety precautions while 3D printing.

- 1.Bravi L, Murmura F, Santos G. Additive Manufacturing: Possible Problems with Indoor Air Quality. Procedia Manufacturing. Published online 2019:952-959. doi:10.1016/j.promfg.2019.10.020

- 2.Gu J, Wensing M, Uhde E, Salthammer T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environment International. Published online February 2019:476-485. doi:10.1016/j.envint.2018.12.014

- 3.Balmes JR, Fine JM, Sheppard D. Symptomatic Bronchoconstriction after Short-Term Inhalation of Sulfur Dioxide. Am Rev Respir Dis. Published online November 1987:1117-1121. doi:10.1164/ajrccm/136.5.1117

- 4.Lowther SD, Deng W, Fang Z, et al. How efficiently can HEPA purifiers remove priority fine and ultrafine particles from indoor air? Environment International. Published online November 2020:106001. doi:10.1016/j.envint.2020.106001

- 5.Wolkoff P, Wilkins CK, Clausen PA, Nielsen GD. Organic compounds in office environments – sensory irritation, odor, measurements and the role of reactive chemistry. Indoor Air. Published online February 2006:7-19. doi:10.1111/j.1600-0668.2005.00393.x

- 6.Sidheswaran MA, Destaillats H, Sullivan DP, Cohn S, Fisk WJ. Energy efficient indoor VOC air cleaning with activated carbon fiber (ACF) filters. Building and Environment. Published online January 2012:357-367. doi:10.1016/j.buildenv.2011.07.002