What are the health risks of 3D printing?

Appropriately dealing with health hazards is (hopefully) nothing new in our workshops and maker spaces, and just with any other tool it is important to analyse and mitigate the health risks, to ensure 3D printing safety. This article concerns common safety hazards of fused filament fabrication printers.

Mechanical Hazards

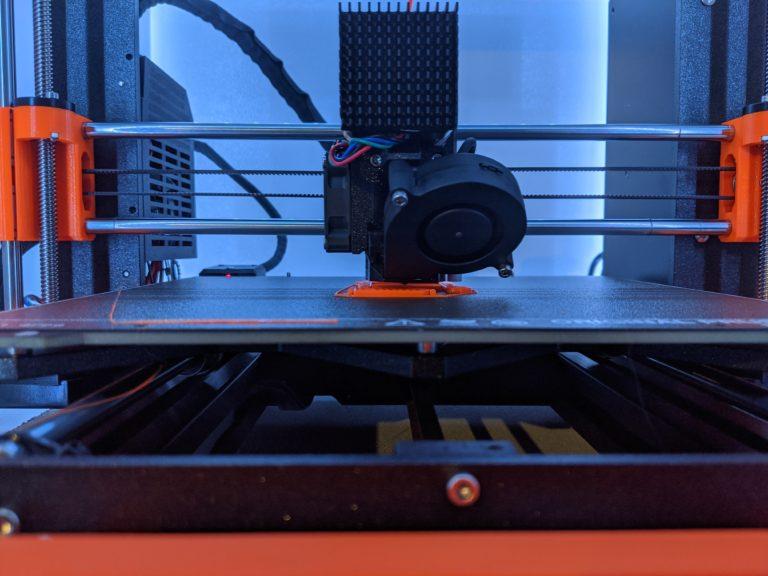

All parts of the 3D printer that move pose the threat of injury. Examples include: flywheels, pulleys, belts, couplings, chains, cranks, gears, etc. The feed mechanisms and auxiliary parts of the 3D printer should also be considered.

Mitigation

- Don’t reach into the printing area while the printer is running.

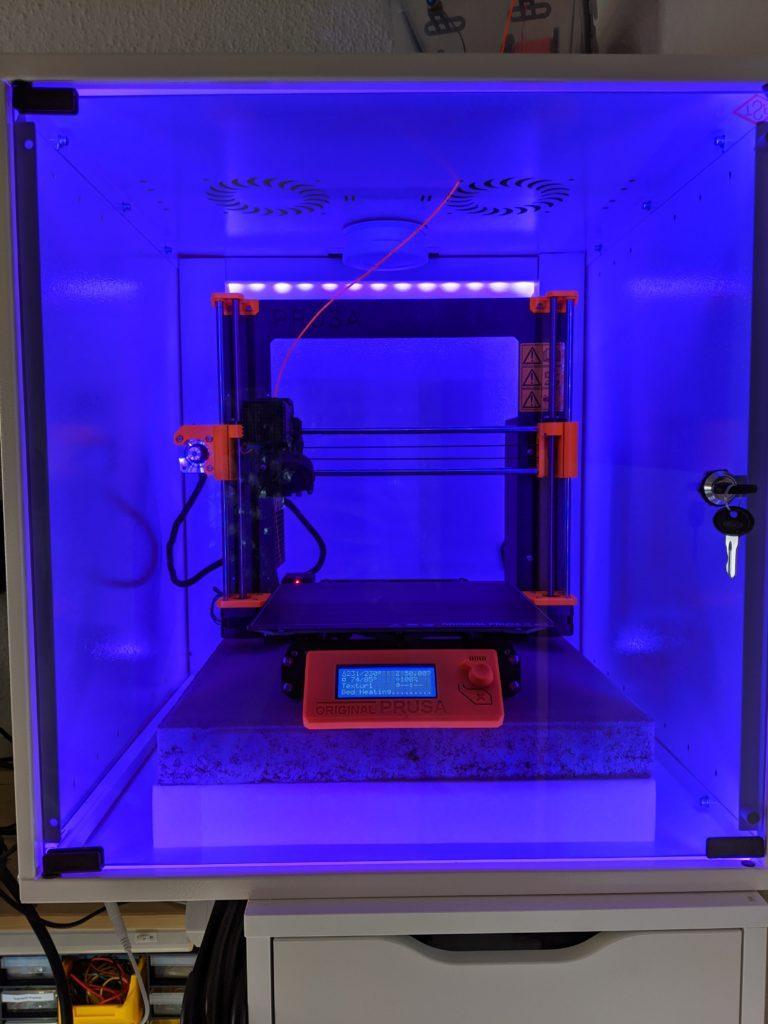

- Run the printer inside an enclosure that protects from accidentally reaching into the printing area.

- Only work on the printer when it is completely de-energized.

Electrical & Fire Hazards

While a properly assembled 3D printer should never have any accessible surfaces exposed to live electricity, they do bear the potential of exposing the user to mains voltage if improperly handled or maintained. Especially low-cost 3D printers tend to cut corners that could create a real fire or electric hazard. While most parts of the 3D printer usually run on 12V or 24V, some heat beds run on mains’ voltage (120-230V depending on where you’re from), and of course, a malfunctioning power supply can pose a significant risk.

Make sure to buy your printer from reputable sources.

Try purchasing your printer from (re)sellers that have a good track record. Legitimate shops will make sure that the items they sell adhere to local laws and have gone through the appropriate import steps if imported from overseas.

Alternatively, be aware that the item you bought might not adhere to local safety laws if you purchase something through AliExpress or some other back channel directly from China. I bought a cheapo heat gun from China and had to resolder the internal connectors.

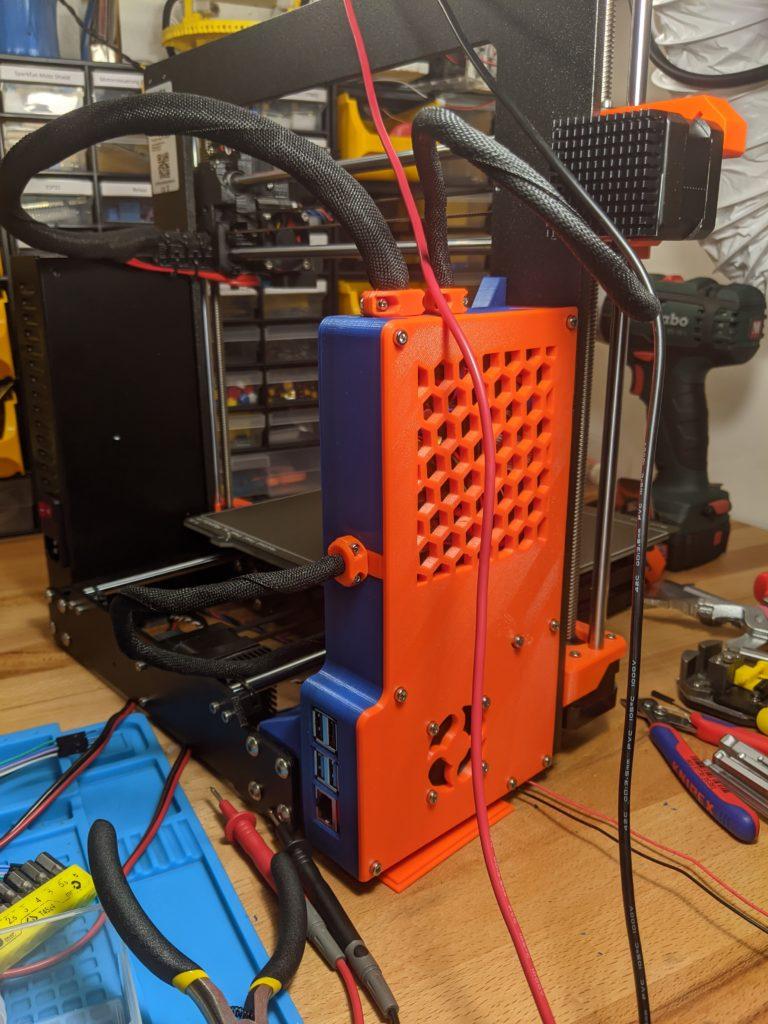

Check wiring and connectors.

Lose connectors lead to higher resistance, leading to higher temperatures, leading to higher resistance. Repeat that a few more times until you have an electrical fire. Ensure all wires are appropriately sized. Especially when buying from, ahem, less reputable sellers, the products tend to be made for the lowest price possible. That means cutting corners left, right and centre. As long as the product doesn’t burst into flames immediately, it gets shipped.

Make sure wires are properly terminated. Do not tin wires that are to be terminated with screw terminals. Invest in a wire crimping tool and several ferrules.

Take preventive measures

Consider running your 3D printer within a metal enclosure, fit a smoke alarm and keep a fire extinguisher nearby.

Do not let the printer run unattended

As enticing as it might seem, unless you have strong reason to be confident in your 3D printer (i.e. it’s a commercial unit), do not leave your printer running unattended. And if you do, at least make sure you can check up on it remotely through something like OctoPrint.

Only work on the printer when it is completely de-energized.

This should go without saying, but make sure to unplug your 3D printer when doing maintenance on it. If you’re not experienced with electronics, you should leave potential electric fixes to someone else.

Temperature Hazards

The most obvious source of burns would be the print bed and the heating block. Print beds can reach temperatures exceeding 100 °C, while heating blocks easily reach 270 °C and above. Both temperatures are high enough to cause burns when touched without appropriate safety gear.

The most obvious source of burns would be the print bed and the heating block. Print beds can reach temperatures exceeding 100 °C, while heating blocks easily reach 270 °C and above. Both temperatures are high enough to cause burns when touched without appropriate safety gear.

Be aware of the hot bits

The most common items of a 3D printer that can become hot are, as stated above, the hot-end, the heat bed and potentially the stepper motors. It might be a good idea to invest in an IR thermometer, which allows you to check the temperature of parts without touching them.

Let it cool down

Except for some maintenance tasks that require the printer to be hot while being worked on, give it time to cool down before working close to the hot parts. Most printers also have a screen that shows you the current temperature the components are at.

Wear protective gloves

Wearing some thin-sleeved work gloves can protect your hands from accidental burns while working on the hotend. Make sure they are rated for higher temperatures, however, otherwise you might have them melt onto you instead.

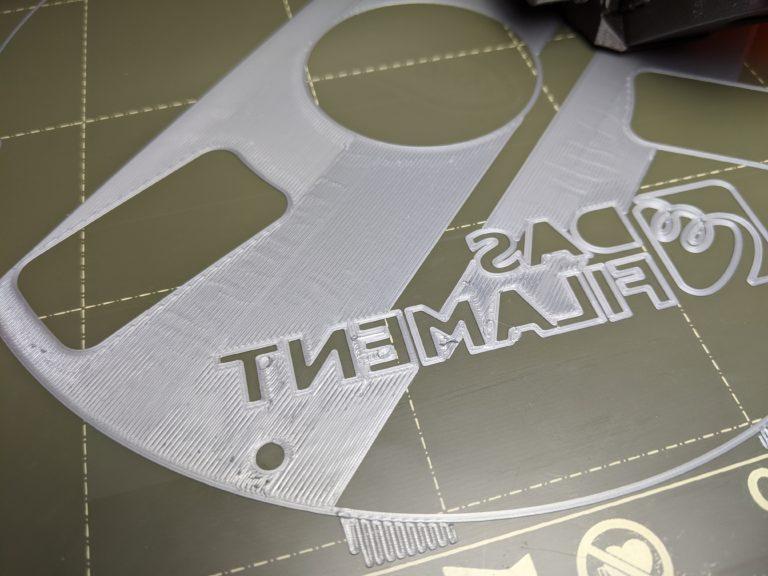

VOC & Dust Emissions

FFF 3D printers are a major source of VOCs and ultrafine particles, both of which can be health hazards. While this can vary drastically on the filament type, it is still advised to reduce your exposure to 3D printer emissions.

Run the 3D printer in a well-ventilated area.

The caution here is that moving (cold) air can seriously deform and ruin your print. Some filaments even require a certain ambient air temperature to behave as expected.

Put the 3D printer in an enclosure.

The enclosure requires appropriate air filter capabilities to completely mitigate the harmful emissions, but it should significantly reduce the exposure.

Invest in an air purifier.

Rather than filtering the air inside the enclosure (which, admittedly, would be more efficient), you can also get an air purifier that continuously filters the air in the room the 3D printer is in. The market is swamped with shady companies that try to upsell you with various technologies that supposedly clean the air even better. Disregard any filter using an ionizer or any other snake-oil filter techniques.

Size does matter in this case; the larger the filter area, the better. It should contain at least a HEPA filter as well as an activated carbon stage. Any others are superfluous.

Wear a respirator

An alternative to filtering the air in the room, you can just filter the air going into your lungs. That can be done by wearing a mask with appropriate filters. That means particulate filters rated at FFP2/3 and activated carbon cartridges.

Chemicals

Some steps in the 3D printing workflow require the use of chemicals, which require various safety considerations. Make sure the gloves are non-reactive, that means either made from neoprene or nitrile. Latex can react with some chemicals and degrade or lose its protective properties entirely.

Isopropyl Alcohol

Isopropyl Alcohol, also known as Isopropanol, 2-propanol and rubbing alcohol, is commonly used when cleaning build plates of 3D printers, and more recently for cleaning up resin prints before curing them. While commonly used in household cleaners, pure isopropyl alcohol is far more dangerous.

To handle IPA safely, as stated by Formlabs:

- Wear disposable non-reactive gloves (nitrile or neoprene) to handle IPA.

- Work in a well-ventilated area.

- Transfer IPA from larger containers with a siphon pump

Acetone

Acetone is commonly used to vapour smooth 3D prints. Also known as propanone, it is a clear, colorless liquid that is highly flammable. It is considered a hazardous waste material and needs to be handled and disposed of properly. The potential negative health effects are skin, eye, and lung irritation. Long-term exposure can result in dry, cracked skin and possible damage to the nervous system.

Handling considerations:

- Make sure the area in which the acetone is used is well-ventilated

- Wear proper PPEs (gloves, goggles, mask)

- If you work with acetone on a surface, make sure the surface it’s a surface that doesn’t soak up the liquid

- If you use acetone in your business, make sure you have got the proper licensing in place to do so

More information can be found here.

Conclusion

3D printing using FFF technology is an overall relatively safe affair, if some simple safety precautions are taken. Always make sure to keep your health and safety in mind, especially when working with 3D printers regularly.